He was the greatest genius, and the most productive engineer of Middle Ages. He spent sleepless nights in this workshop. Without a doubt, Jazari owed his success to his genius. However, when we look at the machines he built, we can see it took days of work to try out many of his ideas. He hammered a parabolic cup’s surface for a thousand times to give it a parabolic shape, and watched the drainage of the water for hours. Jazari was aware of the importance of efforts in addition to an idea, and we can imagine it took the longest times to find the balance for his mechanisms that required sensitive adjustments. On the other hand, Jazari also knew he had to establish a more productive relationship with the materials so that he could apply his ideas, so the improvements he brought in production techniques are as important as his constructional and systemic contributions he made to engineering.

Jazari Waxwork

For waxwork, the most important essentials are the face mold and the physical measures of the subject person. Therefore, if the subject person is not among the living anymore, the artist examines his photographs and tries to get the most realistic measures as possible. Moreover, according to the posture, the body and hands are positioned. Since we don’t have a historical image, we had to reproduce him completely based on our own character design, and his clothing was designed based on the court style of his time. The waxwork in the workshop is positioned in a way to give the impression the guests are welcomed by Jazari himself.

Workshop Bench

Casting Furnace Model

To represent the casting technique of his time, there are a furnace with its bellow, and equipments for casting and molding in Jazari’s workshop. In this setting, Jazari’s position in casting technology, emphasizing the contributions he made in this area. He made two important contributions to casting technique. The first one is the use of molding frames that Jazari called as rulers. With these, he improved the molding technique. The other is the double alloy casting technique where he cast two different metals separately to combine them into one. Jazari cast a pitted structure with the first metal, and keeping the thermal behavior differences of the alloys in mind, he used these pits as molds to cast different metals into them.

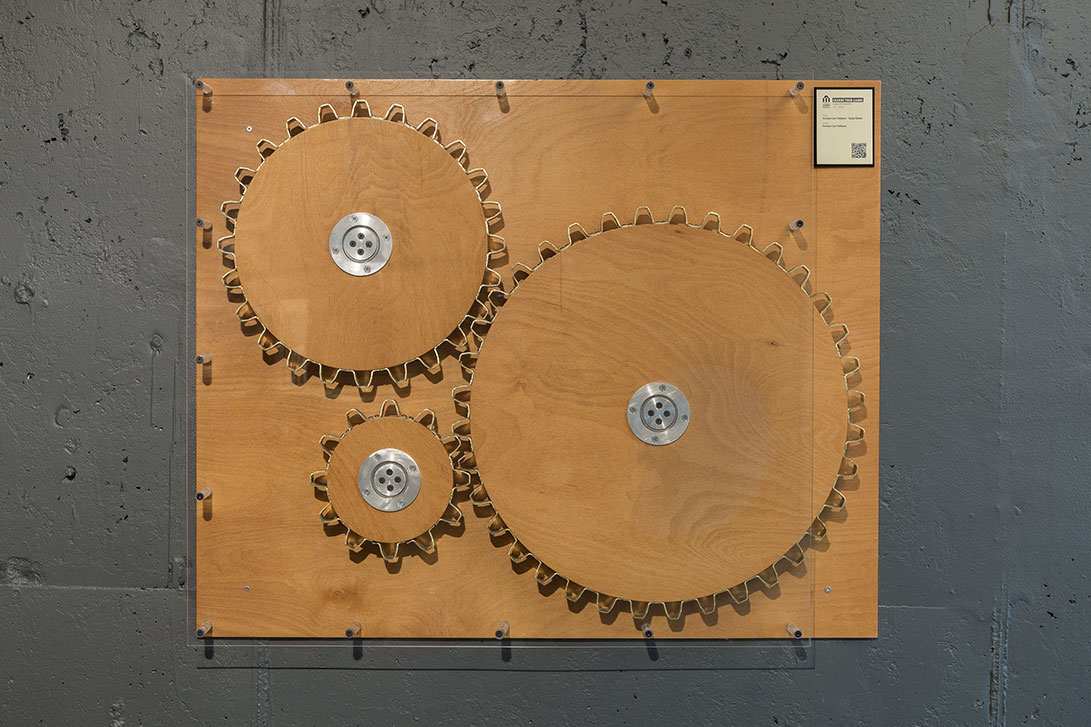

Cogwheels Reconstructed

Cogwheels go far before Jazari’s time. However, we see very important improvements in Jazari’s cogwheels. The classic way to run two perpendicular gears was to use gears with stick notches. Of course, it was a highly unproductive way, and these sticks might break when pushed too hard. Jazari discovered conical notches to use them. Even if these gears were perpendicular, they could hold each other because of their sloped surfaces. Jazari also invented a very productive and durable way for their production. He rolled “n” profiled brass plates and welded them around a wooden wheel. When the cogwheels were supposed to be more durable and powerful, instead of rolling the plates, he cast them with thicker bodies.

Interactive Cogwheel System

In this mechanism that is shown as an example for the cogwheels Jazari used in his machines, you can see the interactive effects of gears that have differing notches and sizes. When you rotate a large gear clockwise, you’ll see two others go in the opposite direction. Also, you can see the rotating speed goes higher as their diameters go larger. In another word, when the large gear rotates a 1 full spin, middle sized gear will go 1.5, and small one 3 spins.